From grocery staples to factory parts, heavy cargo trucks are the keystone that turns global trade into daily deliveries. This week, fleets enter the annual Q4 ramp-up with extra night runs, high-capacity trailers, and precision dispatching to keep shelves stocked. Behind the scenes, telematics, predictive maintenance, and digital documents are shaving minutes at docks and hours at borders, turning reliability into a competitive advantage. With new energy infrastructure coming online and regulators digitizing paperwork, big rigs are moving more freight with fewer delays—often unnoticed, until something isn’t there.

Across hub-and-spoke networks, carriers are leaning on cross-docks, drop-and-hook operations, and inland ports to keep long-haul tractors rolling. This week’s peak-season build-out adds swing drivers and extended gate hours at major distribution centers, reducing queue times and smoothing handoffs. Shippers report fewer missed appointment windows as trucks bypass congestion with live ETA feeds. The practical outcome is tangible: steadier store replenishment cycles and fewer emergency expedites.

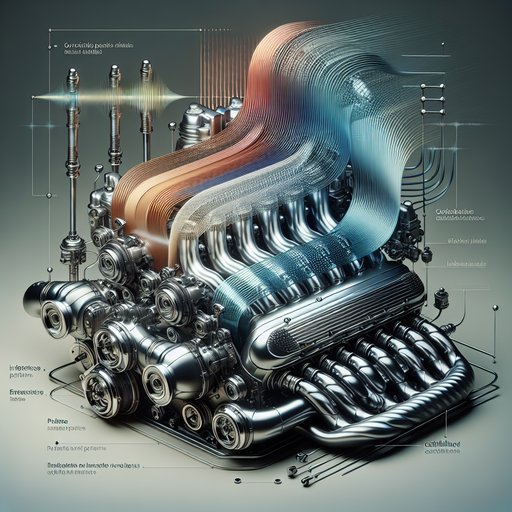

Technology is doing the quiet heavy lifting. Fleetwide telematics flag components for service before failure, while tire-pressure and aero kits trim fuel burn without sacrificing payload. Load-matching algorithms are cutting empty miles on backhauls, and over-the-air updates keep powertrains and safety systems calibrated between depot visits. The net effect is higher tractor utilization and more predictable transit times, especially on high-volume corridors.

Infrastructure and data rules are catching up to the pace of freight. The EU’s electronic freight transport information framework, applicable since August 2024, allows authorities to accept digital consignment data, shortening roadside checks and border stops. Megawatt charging–ready depots and hydrogen refueling pilots added this year on key lanes enable same-shift turnarounds for zero-emission rigs on 300–500 km routes. Together, these changes trim dwell time at yards and make energy planning as routine as fuel card swipes.

Resilience is now part of the daily playbook. When extreme weather or a port hiccup hits, carriers pre-position trailers, reroute via secondary intermodals, and rely on real-time weight and bridge data to stay compliant and moving. This week, seasonal restocking runs are staged with buffer capacity, so a late container doesn’t cascade into empty shelves two states away. Driver training and retention programs, paired with safer cab tech, keep experienced hands in the seat when demand spikes.

The result is simple but crucial: big trucks arrive, loads transfer, and supply chains stay invisible in the best possible way.