From the outlawing of ground-effect tunnels in the early 1980s to the modern budget cap and the recent return of venturi floors, Formula 1 has been defined as much by its rulebook as by its racers. Each major regulation shift has redrawn the competitive map, reshaped how teams spend, and redirected engineering focus. The sport’s constant calibration between safety, spectacle, and sustainability forces competitors to adapt quickly, turning constraints into opportunities and loopholes into race-winning innovation.

In Formula 1, regulations are the most influential performance part on the car. When the FIA rewrites the rules, it resets priorities—sometimes subtly, sometimes completely—forcing teams to reframe their design philosophies, operations, and racecraft. These resets often arrive to serve multiple masters at once: safety, competitive balance, cost control, and on-track spectacle. The evolution of F1 is therefore best read through its rule changes, and through the ways teams learn to win within new boundaries.

The first modern reset came with the end of the original ground-effect era. In the late 1970s, venturi tunnels and sliding skirts produced immense downforce, but also alarming ride-height sensitivities that magnified safety risks. For 1983 the FIA mandated flat bottoms to kill the tunnels, pushing teams back toward wings and cleaner underfloors. The best-adapting outfits shifted emphasis to turbocharged power and refined aerodynamics, recovering lost grip with horsepower and smarter airflow rather than raw suction.

The resulting “power wars” defined strategies around fuel, reliability, and qualifying boost, not just cornering speed. Electronics drove the next big pivot. Williams’ early-1990s mastery of active suspension and driver aids showcased the potential of software and hydraulics to stabilize platforms and generate consistent aero. Ahead of 1994 many of those aids—active suspension, traction control, and ABS—were banned, and after the season’s tragedies the FIA imposed additional safety-minded measures, including skid blocks in 1994 and a stepped floor in 1995.

Teams redirected effort into mechanical grip, aero efficiency at higher ride heights, and more predictable handling. Race strategies adjusted as drivers managed tyres and brake temperatures without electronic crutches, emphasizing chassis balance and driver feel. The 2009 aerodynamic overhaul sought to improve racing by reducing wake sensitivity and simplifying bodywork. It inadvertently produced one of F1’s famous loophole stories: the double diffuser, pioneered by Brawn GP and also used by Toyota and Williams, which recovered huge downforce within the letter of the rules.

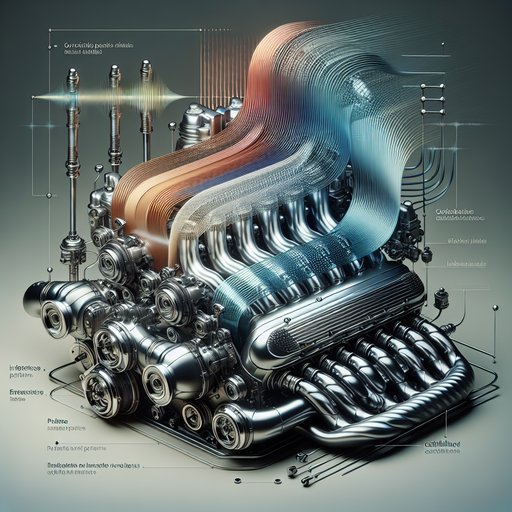

Rivals had to re-architect their rear ends mid-season to catch up, proving how interpretation can be as decisive as innovation. KERS debuted the same year as an optional system, forcing trade-offs between packaging, weight, and tactical deployment, and foreshadowing the energy-management chess that would later define the hybrid era. That era arrived in 2014 with 1.6‑liter turbo-hybrid power units, strict fuel-flow limits, and complex energy recovery through MGU-K and MGU-H. Mercedes set the benchmark by tightly integrating the engine, turbo, and energy systems—packaging that improved both efficiency and aerodynamics—then built a factory process that iterated relentlessly within development token limits.

Strategy expanded beyond tyres and fuel to include battery state-of-charge, deployment maps, and thermal management, with software becoming a race-winning tool. Later aero changes, such as the higher-downforce 2017 cars and the simplified 2019 front wings, shifted design trends toward floor load, rake concepts, and outwash control, forcing teams to rebalance peak downforce against raceability. The most profound off-track reset arrived in 2021 with the financial regulations. A hard budget cap began at $145 million, stepped down to $140 million in 2022 and to $135 million in 2023 (with permitted adjustments), fundamentally altering how teams plan seasons.

Complementary Aerodynamic Testing Restrictions introduced a sliding scale of wind-tunnel and CFD time linked to championship position, sharpening the opportunity for underdogs to catch up. Enforcement added teeth: Red Bull’s 2021 cost cap breach led to a fine and reduced aerodynamic testing time, illustrating tangible performance consequences. Across the grid, organizations restructured, upgrade cadences became more selective, and simulation gained primacy as the cheapest lap time. Then came 2022 and the return of ground effect—this time via underfloor tunnels, simplified wings, and 18‑inch tyres designed to tame wake and improve following.

The unintended star was porpoising: aeroelastic oscillations that forced teams to rethink floor stiffness, suspension kinematics, and ride-height windows, while the FIA’s TD039 and subsequent floor tweaks for 2023 tightened compliance. The most competitive packages blended efficient underfloor load with robust platform control, cooling headroom, and DRS-friendly aero, making floor R&D the main battleground. As concepts converged, update strategies prioritized floor edges, diffuser throats, and rear-corner packaging, areas with the highest cost-to-laptime return under the cap. The through-line is adaptation.

Each ruleset rewards those who align engineering, operations, and race strategy to the new constraints faster than rivals, whether that means leaning into turbo power after 1983, mastering energy management after 2014, or industrializing cost‑cap governance after 2021. With the FIA outlining the direction of the 2026 era—lighter, lower-drag cars paired with revised hybrid power units and an emphasis on efficiency—teams are already modelling scenarios to de-risk concepts before the next reset. In a sport defined by change, the winners are the ones who read the rulebook as a design brief, not a restriction, and turn its boundaries into their competitive advantage.