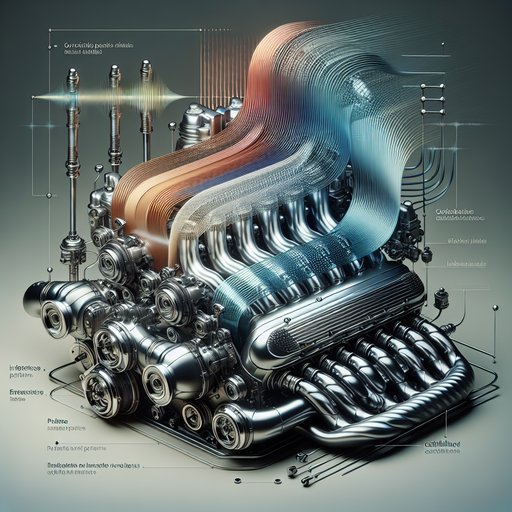

Intake systems can do more than deliver air—they can time pressure waves to boost torque and use side-branch volumes to cancel boom. Runner length exploits quarter-wave reflections so a positive pressure wave arrives near intake valve closing, improving cylinder filling. Resonators target narrow frequency bands tied to engine orders, flattening cabin drone without adding backpressure. With a few equations and practical rules-of-thumb, you can pick lengths and volumes that land the torque bump where you want it and knock down NVH hotspots, all while keeping flow losses low and packaging realistic.

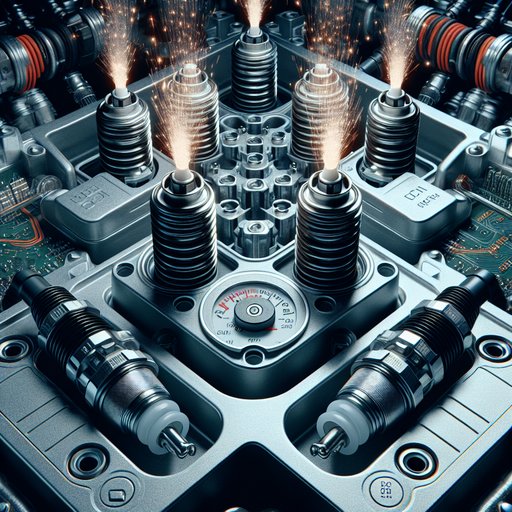

Ignition systems must light mixtures reliably across cold starts, idle EGR, high-rpm, and boosted full-load. Coil‑on‑plug (COP) architectures shorten the high-voltage path and allow per‑cylinder control, but success hinges on precise dwell management, suitable spark plugs, and robust diagnostics. Under boost, higher in‑cylinder pressure pushes breakdown voltage and energy demand up, stressing coils and plugs. Modern ECUs juggle battery voltage, temperature, lambda, and rpm to maintain spark energy without overheating coils. Meanwhile, on‑board misfire detection protects emissions hardware and guides service. This overview links COP hardware, dwell strategy, plug design, boosted ignition needs, and misfire monitoring into a coherent picture.

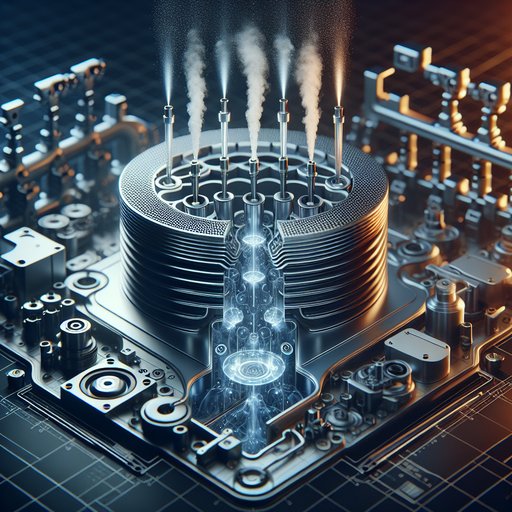

Gasoline direct injection (GDI) improves efficiency and knock tolerance via in-cylinder charge cooling, but it raises particulate number (PN) emissions relative to port fuel injection (PFI). The root cause is mixture preparation: a spray that touches cold metal or forms locally rich pockets can create soot precursors even when the overall mixture is stoichiometric (lambda ≈ 1.0, AFR ≈ 14.7:1). Engineers attack this with precise injector targeting and timing, higher rail pressures, and sometimes dual injection (PFI + GDI). A gasoline particulate filter (GPF) is the safety net, enabling robust compliance in real-world conditions while preserving GDI’s efficiency benefits.

Fatty acid methyl esters (FAME, EN 14214) and hydrotreated vegetable oil (HVO, paraffinic diesel per EN 15940) both cut fossil carbon but behave very differently in engines and logistics. FAME is an oxygenated ester with good lubricity but limited cold flow and oxidative stability; HVO is a sulfur- and aromatic‑free paraffin with very high cetane, excellent cold performance, and strong storage stability but low density and lubricity. Blends with EN 590 diesel are common: B7–B10 for FAME and 10–100% for HVO. Understanding cetane, cold filter plugging, storage stability, and injector deposit control is crucial to avoid drivability issues and maintain aftertreatment durability.