Gasoline direct injection (GDI) improves efficiency and knock tolerance via in-cylinder charge cooling, but it raises particulate number (PN) emissions relative to port fuel injection (PFI). The root cause is mixture preparation: a spray that touches cold metal or forms locally rich pockets can create soot precursors even when the overall mixture is stoichiometric (lambda ≈ 1.0, AFR ≈ 14.7:1). Engineers attack this with precise injector targeting and timing, higher rail pressures, and sometimes dual injection (PFI + GDI). A gasoline particulate filter (GPF) is the safety net, enabling robust compliance in real-world conditions while preserving GDI’s efficiency benefits.

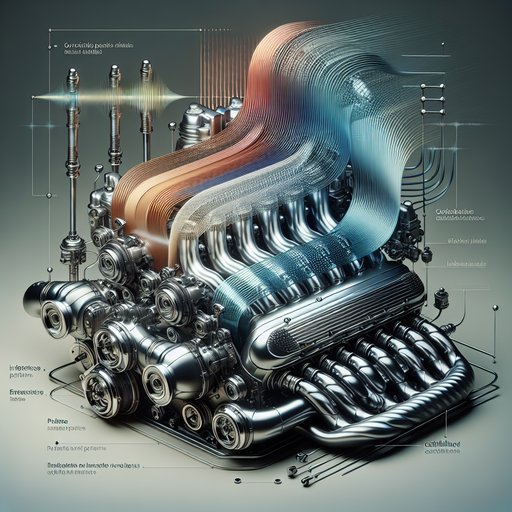

GDI places fuel directly into a tumbling, moving air charge. The geometric relationship among injector, valve axes, and piston crown determines how the spray breaks up, evaporates, and mixes before ignition. Central, multi-hole injectors with 60–80° cone angles favor homogeneous, stoichiometric operation with a three-way catalyst (TWC). Side-mounted, narrow-cone sprays can support stratified lean concepts, but most markets run stoichiometric to simplify aftertreatment.

The early design goal is the same: keep liquid fuel off cold walls and avoid rich pockets near the spark at light load, while still leveraging in-cylinder cooling for knock control at high load. Targeting blends hardware and calibration. Hardware sets spray plume count, cone angle, and penetration; 200–350 bar rail pressure is common, raising atomization quality (smaller Sauter mean diameter) and reducing penetrative wall hits. Calibration sets injection phasing and splitting.

Early-cycle (intake stroke) injections let the spray ride tumble, increasing vaporization time; late injections increase charge-cooling but heighten impingement risk. Split injections—e.g., 60/40 mass splits across intake and early compression—can manage both evaporation and knock. Piston crown features (bowls, deflectors) steer plumes away from the liner and toward tumble cores. Wall wetting is the principal driver of PN in GDI.

When droplets strike the liner, piston, or valve faces—especially on cold start (wall temps < 60°C, low in-cylinder pressure)—liquid films form. These films can survive to ignition, then burn as “pool fires,” generating soot nuclei in locally rich zones (equivalence ratio φ > 1.2–1.4) even while the global lambda remains ≈1.0. Under tip-in enrichment (λ ≈ 0.85–0.95) and during catalyst light-off, PN spikes are common. Raising pressure to 350+ bar, tightening targeting, using multi-pulse strategies, and modest oxygenation (E10–E20) can cut PN by 20–50% by shrinking droplets, speeding evaporation, and suppressing soot chemistry.

Compared with PFI, GDI typically shows higher PN (often 3–10× on transient cycles) because PFI premixes fuel with warm intake air and avoids in-cylinder films. PFI, however, sacrifices some knock margin (less charge cooling), and can exhibit higher cold-start HC and intake valve deposits. Dual injection combines strengths: use PFI at cold start and low load to minimize wall wetting and PN, then blend toward GDI as load rises to exploit charge cooling and precise cylinder balancing. Calibrations commonly run PFI-dominant below ~2–3 bar BMEP or during catalyst heating, and GDI-dominant above, with dynamic splits; PN reductions of 30–60% versus GDI-only are achievable while retaining GDI fuel economy at medium/high load.

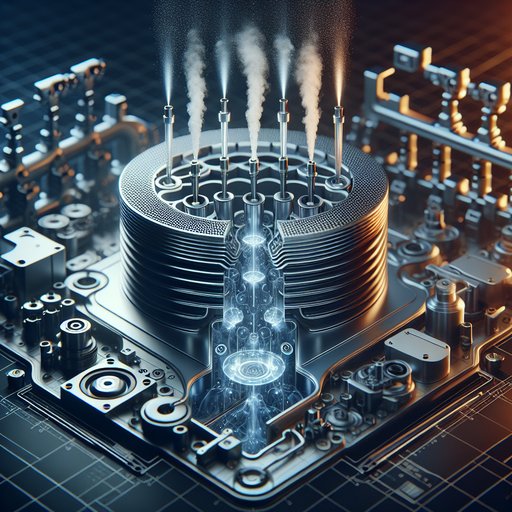

Even with careful targeting and dual injection, real-driving emissions (RDE) with rapid transients, altitude, and temperature swings can push PN above lab limits. The Euro PN limit is 6×10^11 #/km; modern coated GPFs (cGPF) provide 75–95+% PN reduction, routinely driving tailpipe PN below 1×10^11 #/km on WLTP/RDE. A wall-flow GPF adds 5–20 kPa backpressure at rated flow, modestly increasing pumping work. Stoichiometric gasoline exhaust temperatures (400–800°C) enable passive regeneration; the TWC coating maintains CO/HC/NOx conversion.

Over life, ash accumulation raises pressure drop; design margins and periodic high-temp operation manage this with a small (≈0.5–2%) fuel penalty. The practical playbook is: design sprays and piston crowns to avoid impingement, run high rail pressure with split injections to balance evaporation and knock, deploy dual injection to quash cold-start and low-load PN, and fit a GPF to guarantee compliance under RDE. Reliability benefits follow—less oil dilution and fewer deposits from reduced wall wetting lower LSPI risk. Emissions are robust across environments with a cGPF backstop.

Cost rises with dual systems and the filter, and there is minor backpressure, but drivability remains strong: smooth mode blending avoids torque steps, and stoichiometric control preserves catalyst performance while delivering the efficiency and response expected of modern GDI.