Abstract art sparked by the language of the automobile is having a visible moment across galleries, museums, and salerooms. In May, Julie Mehretu’s 20th BMW Art Car—an abstract wrap derived from her layered paintings—was unveiled at the Centre Pompidou before competing at the 24 Hours of Le Mans in June, drawing design devotees into an art context. At the same time, auction houses reported steady bidding for car-derived abstractions, from crushed–auto-body sculpture to minimalist “hood” works, suggesting durable crossover appeal among collectors of art and motorsport design.

Solid-state batteries promise step-changes in energy density and safety by replacing flammable liquid electrolytes with inorganic or polymer solids and enabling lithium-metal anodes. The upside is compelling: 20–50% higher cell-level energy, improved abuse tolerance, and potentially faster charging. Yet core physics and manufacturing realities—dendrite control, interfacial stability, layer uniformity, moisture sensitivity, and yield—govern whether the promise translates into mass-market packs. Companies like QuantumScape and Solid Power have advanced multi-layer prototypes, but moving from lab cells to 20–100 Ah automotive formats at high yield and low cost remains the central challenge for the decade.

Homogeneous Charge Compression Ignition (HCCI) and Reactivity Controlled Compression Ignition (RCCI) pursue the same goal—diesel-like efficiency with ultra-low NOx and soot—via different control levers. HCCI relies on autoignition of a near-homogeneous, typically lean charge; RCCI layers fuel reactivity in-cylinder using two fuels to steer when and where heat is released. Their feasibility hinges on fuel chemistry (octane/cetane), temperature and dilution windows, and how precisely phasing can be managed. The comparison below highlights control difficulty, usable load/speed range, temperature sensitivity, and hybrid blending strategies that bridge to more conventional spark-ignition (SI), diesel, and partially premixed combustion modes.

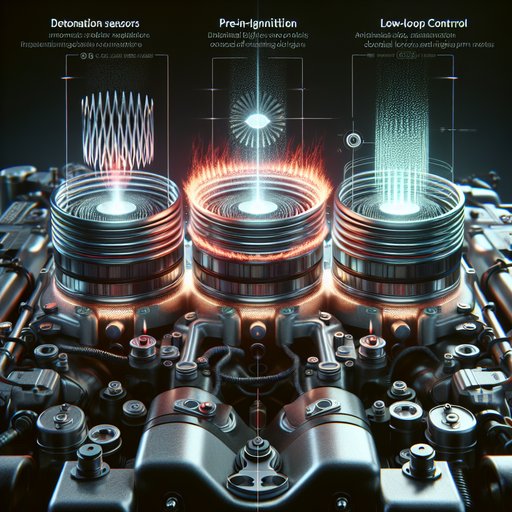

Abnormal combustion in spark-ignition engines appears in three distinct forms: detonation (knock), pre‑ignition, and low‑speed pre‑ignition (LSPI). They differ in when ignition occurs, how pressure rises, and the resulting damage risk. Modern controls—knock sensors, ion‑sensing at the spark plug, and closed‑loop spark/boost—manage each with tailored strategies. Understanding the mechanisms and the sensing windows is critical, because knock is often manageable and even allowed at low levels, while pre‑ignition and LSPI are stochastic and potentially catastrophic, demanding rapid detection and torque reduction rather than the gentle spark trimming used for ordinary knock.