Before the headlines and hearings, the scandal took shape in meeting rooms where marketing promises outran physics, and in lab cells where tidy curves hid messy realities. In 2015, the Volkswagen diesel emissions crisis broke wide open, but its roots reached back through a decade of policy incentives, engineering compromises, and a belief that software could reconcile the irreconcilable. What followed reconfigured regulatory playbooks on both sides of the Atlantic and recast how drivers, dealers, and lawmakers think about trust in a world where cars are as much code as metal.

Battery-electric and hydrogen-powered cargo trucks are crossing key thresholds, turning demonstrations into daily duty. On the electric side, megawatt-class charging is moving from lab tests to depot pilots, and long-haul tractors like Mercedes‑Benz’s eActros 600 and new-generation models from MAN, Volvo, and Scania are entering customer trials with ranges fit for regional and corridor freight. Hydrogen programs are scaling, too: Daimler Truck’s liquid hydrogen GenH2 proved 1,000‑plus kilometers on a single fill, while Hyundai, Toyota–PACCAR, and Nikola expanded fuel-cell deployments for drayage and regional haul. Paired with fresh rules in Europe and U.S. state-level mandates, infrastructure buildouts are giving fleets clearer paths to cut emissions without surrendering payload or uptime.

Euro 7 for passenger cars and light vans is evolutionary rather than radical: most lab tailpipe limits stay near Euro 6, but durability, particle counting, on-road conformity, and monitoring tighten. The headline shifts are 200,000 km/10‑year emissions durability, counting ultrafine particles down to 10 nm (PN10) and extending PN limits to all spark‑ignition engines, plus on‑board monitoring of real‑world emissions performance. These changes push larger, more robust aftertreatment, better cold‑start thermal management, and sensor-heavy diagnostics. The net effect is cleaner lifetime performance with modest fuel and cost penalties, particularly for small diesel and port‑fuel‑injected gasoline cars.

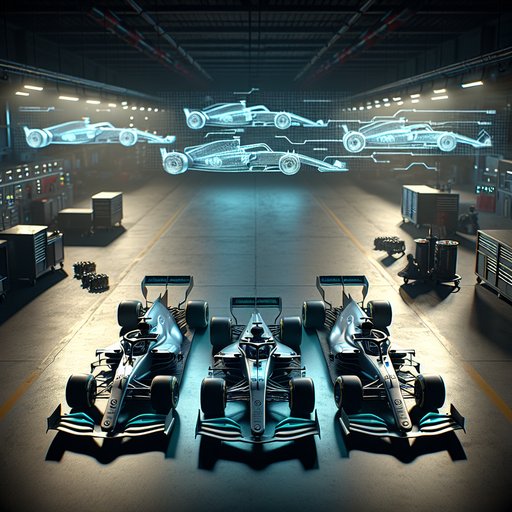

From the still-new Formula 2 chassis bedding in across its second season to the debut of Formula 3’s next-generation car this year, the FIA single-seater pathway has entered a fresh phase in 2025. The latest technical and sporting updates continue to tighten cost control, sharpen safety and sustainability, and clarify how talent is measured on the road to Formula 1. Together, they are shaping how teams and drivers compete right now.

Formula 2’s big change came last season with the launch of the Dallara F2 2024, which replaced the long-serving previous car. Now into its sophomore year, the chassis has matured, with teams and drivers adapting to its revised aerodynamics, stronger side-impact structures and more ergonomic cockpit. The Mecachrome V6 turbo and 18-inch Pirellis remain, but the aero package has already produced noticeably closer racing, while improved safety features have been tested in real-world incidents with positive outcomes. Sustainable fuel and tyre operations without blankets are fully embedded, keeping the series aligned with Formula 1 technology while maintaining predictable costs.