The European Union is taking significant steps to reshape its automotive landscape through new regulations and initiatives aimed at maintaining competitiveness while advancing sustainability goals. Recent data and policy announcements reveal a complex balance between environmental targets and market realities, as European automakers face increasing global competition.

The luxury automotive segment is witnessing a remarkable transformation as premium manufacturers unveil groundbreaking vehicles at Europe's biggest motor show of the decade in Munich. From Ferrari's historic nameplate revival to Mercedes-Benz's breakthrough in EV technology, the industry's elite brands are showcasing their vision for the future of high-end mobility [1].

The electric vehicle market is experiencing significant turbulence as automakers respond to changing market dynamics and upcoming policy changes. With the federal tax credit for electric vehicles set to expire, manufacturers are implementing aggressive pricing strategies to maintain sales momentum, while market share distributions continue to evolve in unexpected ways.

The European automotive sector is experiencing contrasting developments as manufacturers navigate various challenges and opportunities. While some legacy brands showcase resilience at Europe's largest motor show, others face operational disruptions, and luxury manufacturers unveil ambitious new models, highlighting the industry's dynamic nature.

European automakers are grappling with significant market shifts as traditional manufacturers, particularly German brands, face increasing pressure from electric vehicle competitors. The transformation of the automotive landscape has been marked by changing consumer preferences and stringent environmental regulations, forcing established players to reassess their strategies and market positions.

China's new energy vehicle (NEV) market is experiencing significant changes in market dynamics, with domestic manufacturer BYD cementing its leadership position while international competitors face mounting pressure. Recent market data shows a clear shift in consumer preferences and manufacturer standings, reflecting China's evolving automotive landscape and the increasing competitiveness of local brands.

Tesla, once the undisputed leader in electric vehicles, is experiencing a significant decline in its U.S. market share as traditional automakers and new entrants expand their electric vehicle offerings. Multiple reports indicate that Tesla's position in the EV market has reached its lowest point since the introduction of the Model 3 [1].

Several leading car manufacturers are unveiling ambitious plans for new electric vehicles, signaling a significant shift in the automotive industry's electrification efforts. The announcements come as global plugin vehicle registrations reached 1.6 million units in July, representing a 26% market share and a 19% year-over-year increase [1].

As the automotive industry navigates changing market dynamics, electric vehicle manufacturers are rolling out aggressive incentives to boost sales before key tax credits expire. Several automakers are offering unprecedented lease deals and discounts, while government programs add extra savings for consumers looking to go electric [1].

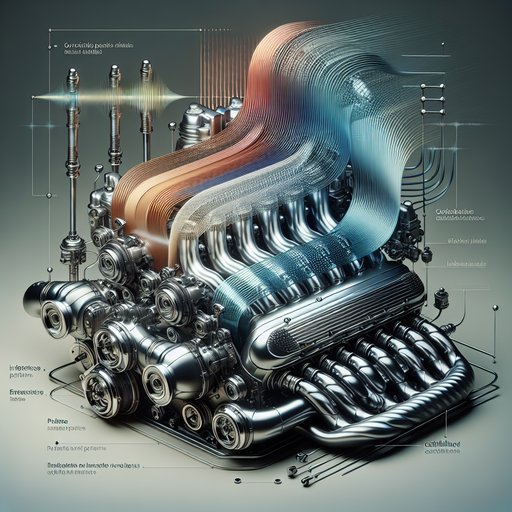

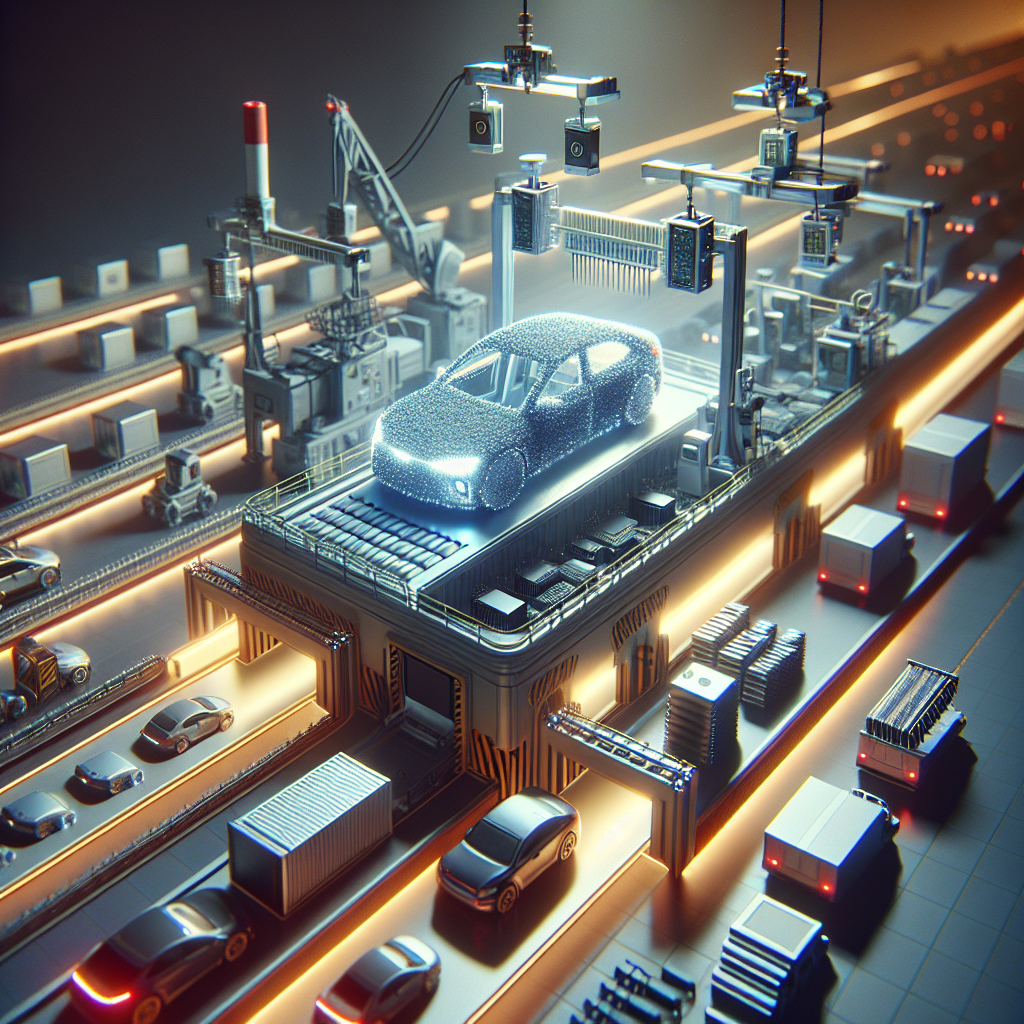

Semiconductor strength, shifting electric-vehicle incentives, and a pair of operational shocks are reshaping the near‑term outlook for mobility supply chains. Foundry leader TSMC extended its dominance in advanced chips, while analysts struck a bullish note on a key U.S. chip designer—signals that the upstream technology backbone remains resilient. In EVs, fresh discounts and aggressive leasing in some markets contrast with tariffs and taxes elsewhere, complicating battery demand planning. Automakers continue to recalibrate production and product pipelines, even as a cyber incident and a labor‑law enforcement action highlight how non‑material risks can still bottleneck output. The overall picture is a sector adapting in real time: capacity where it counts, policy tailwinds and headwinds in parallel, and logistics teams working through disruptions with an eye on recovery.