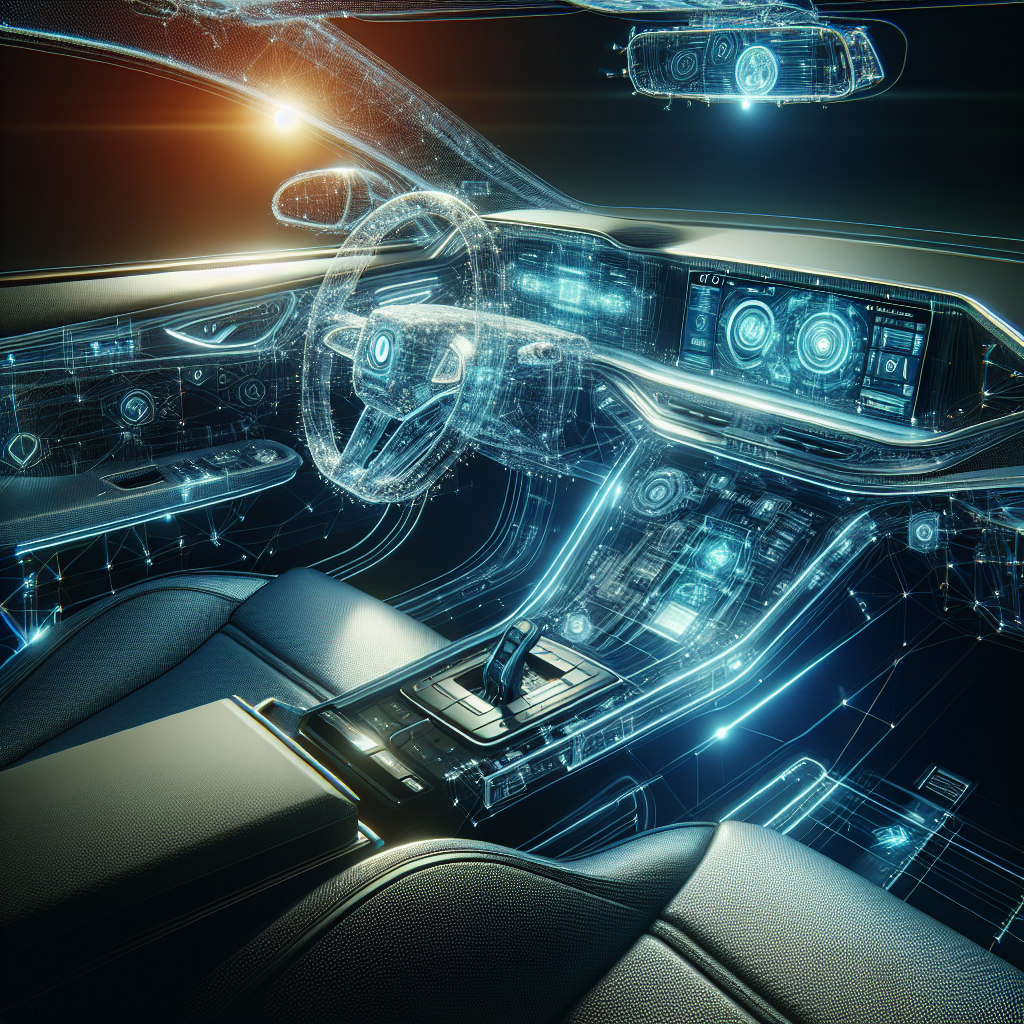

The automotive industry is witnessing a significant transformation in electrical and electronic (E/E) architecture, with major manufacturers adopting advanced Ethernet-based systems. This evolution is particularly evident in the latest developments from leading automakers, who are integrating sophisticated networking solutions to support the growing demands of electric vehicles and their increasingly complex systems.

The automotive sector's embrace of Ethernet-based architectures represents a crucial shift from traditional wiring systems. This transition enables significantly improved data transmission speeds and more efficient power management across vehicle systems. Ethernet's proven track record in enterprise networking is now being leveraged to address the unique challenges of modern vehicles, particularly in managing complex battery and charging systems [1].

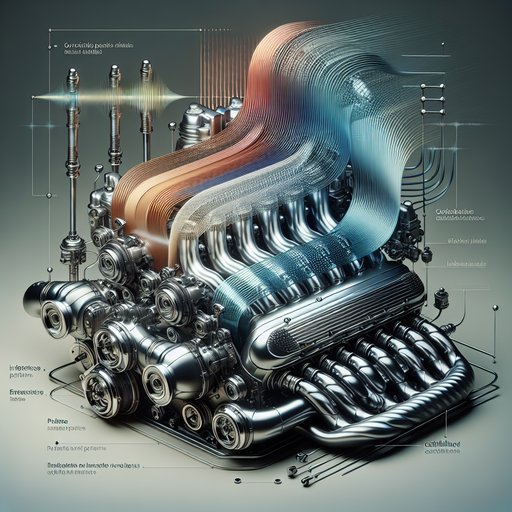

Stellantis is at the forefront of this transformation, implementing new E/E architectures that eliminate the need for separate charger and inverter components. This integration not only reduces system complexity but also improves overall efficiency and range in their electric vehicles. The streamlined architecture allows for more efficient battery packaging and enhanced power distribution [2].

The advancement in E/E architecture is particularly significant for next-generation battery technologies. Mercedes and its partners are developing solid-state batteries that require sophisticated power management and control systems. These new batteries, slated for production vehicles, demonstrate how improved electrical architectures can support advanced energy storage solutions [3].

The integration of modern Ethernet-based systems is enabling manufacturers to implement more sophisticated features, from advanced driver assistance systems to over-the-air updates. This architectural evolution is crucial for supporting the increasing computational demands of modern vehicles while ensuring reliable, high-speed data transmission between various vehicle systems [1].